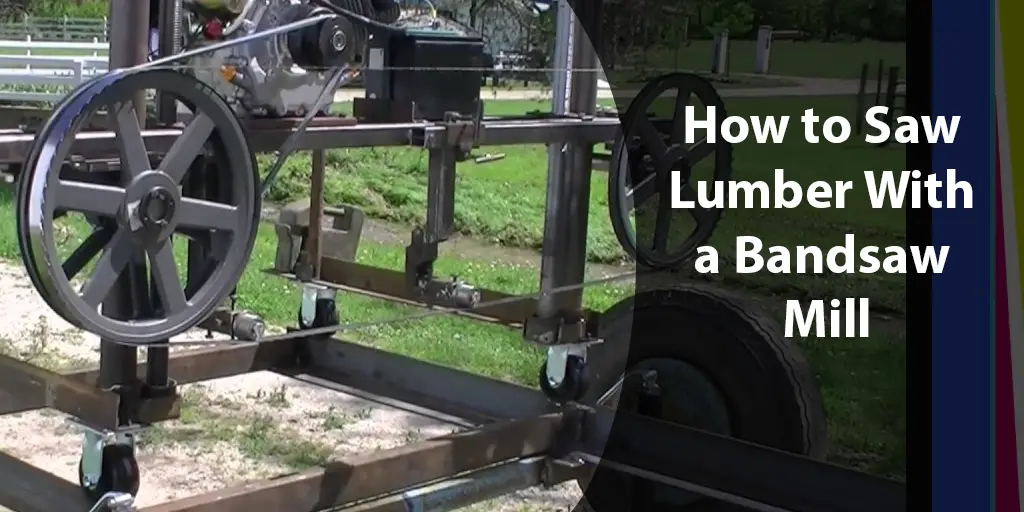

For countless woodworkers and hobbyists, a bandsaw mill offers an accessible and efficient way to turn logs into usable boards and planks.

A bandsaw mill is a versatile woodworking tool that allows you to mill lumber from felled trees right in your own backyard or workshop.

It has gained popularity as an environmentally-friendly alternative to large-scale sawmills, helping turn fallen or culled trees into beautiful lumber while avoiding waste.

Using a bandsaw mill is also an engaging and educational process. You’ll learn about different sawing techniques, how to maximize your lumber yields, and gain a deeper understanding of wood properties and grain patterns.

With some practice, you can produce high-quality dimensional lumber, live edge slabs, and flitches suitable for furniture building or other woodworking projects.

For those new to the process of sawing lumber, a bandsaw mill provides a low-cost entry point compared to other stationary sawmill options.

Models are available to suit budgets large and small, with features ranging from manual hand-fed mills to hydraulically-driven mills capable of large throughput.

The bandsaw itself runs on inexpensive reciprocal bandsaw blades rather than large circular saw blades. Setup and use requires only a log, your bandsaw mill, and basic woodworking knowledge.

In this comprehensive guide, we’ll cover everything you need to know to get started with a bandsaw mill safely and efficiently.

We’ll discuss factors to consider when selecting your bandsaw mill, proper safety procedures, the step-by-step sawing process, different sawing techniques and how to get the most yield from each log.

We’ll also provide troubleshooting tips to optimize your mill’s performance and produce high quality boards with minimal waste. By the end, you’ll have the confidence and knowledge to start milling lumber from logs at home or on your woodworking job sites.

Choosing the Right Bandsaw Mill for Your Needs

The first decision when getting started with a bandsaw mill is selecting the appropriate machine. This crucial choice will depend on several factors, such as your budget, the size and quantity of logs you plan to mill, and the intended use of the lumber.

When it comes to pricing, expect to spend anywhere from $1,000 for a basic manual mill up to $15,000 or more for an industrial-grade hydraulic mill.

Manual mills work well for occasional hobby use but can be tiring for long mills. Semi-automatic mills add hydraulic features like electric log turning that boost efficiency.

Be sure to consider the maximum log size your mill can accommodate. Homeowner models typically handle logs up to 30 inches or less in diameter.

Larger portable mills may saw diameters over 3 feet wide. The length of saw bed also impacts the maximum board length that can be milled.

Extra features like hydraulic log loading/unloading, multiple blade speeds, variable blade tensioning, and remote controls provide more versatility.

Some mills even add upgraded blades, livestock fencing, log deck extensions and other useful accessories.

Portability is also a factor if you intend to use your mill on remote job sites rather than a home workshop. Make sure it can be disassembled for transport in parts small enough to fit in your vehicle. You’ll also need a trailer for large hydraulic mills.

Do your research to determine which features suit your budget and milling needs best. Reliable brands include Norwood, Plum Creek, Wood-Mizer and Speeco.

Read reviews and ask experienced owners for recommendations too. Choosing the right mill up front saves hassle and ensures optimal lumber productivity for years to come.

Proper Setup Is Crucial for Safe and Effective Milling

Once you’ve selected your bandsaw mill, it’s important to take the time for correct setup before attempting to saw any logs. Proper leveling and positioning will allow your machine to operate efficiently while minimizing vibration.

First, find a suitable location with level ground to accommodate the mill’s full length. Concrete is ideal, but compacted gravel or soil will also work if level. For safety, choose an open area away from overhead branches or power lines.

Level your mill from side to side and front to back using wooden blocks and a long bubble level. The tracks that guide the log carriage must be perfectly level for straight accurate cuts. On hydraulic mills, also level out the log deck and hydraulics for smooth operation.

Position the mill so the operator has easy access to all controls while safely standing next to the spinning blade. Allow sufficient room on both sides for positioning and maneuvering large logs as well.

Secure the mill frame to the ground using stakes, concrete blocks or straps to prevent any walk or shift during milling. Vibrations from the powerful blade can cause an unsecured mill to move out of alignment.

With the mill now level and stable, calibrate measurements on the blade guide and log carriage stops. Dial in the desired cut widths using the machine’s measuring guides before milling starts.

Taking time for precise setup pays off in straighter, squarer boards with less wastage. Proper setup creates a safer, more efficient milling experience right from the start.

The Step-by-Step Bandsaw Milling Process

Now that your mill is set up properly, it’s time to break down that log into beautiful lumber. Follow these steps for a safe, efficient milling experience:

Begin by selecting the optimal log orientation depending on the desired cut type. Choose the highest grade cuts first to maximize yield. Inspect logs closely for defects before milling.

Secure the log firmly to the mill deck using log dogs, clamps or other restraints. Hydraulic mills will automatically turn logs as needed.

Adjust the log carriage and blade guides appropriately based on the log’s size and your desired cut widths. Measure twice to ensure accuracy.

Start the mill’s engine and allow the blade to reach proper cutting speed, usually 1,500-3,000 RPM depending on blade material and tooth configuration.

Engage the blade slowly by rolling the log against the teeth, or use electric controls if equipped. Apply gentle even pressure as the blade bites into the wood.

Once cutting, slowly advance the carriage at a pace allowing dust and chips to clear while maintaining full blade penetration. Apply more pressure as needed.

Keep your work area tidy and remain vigilant of safe blade proximity. Blade breakage, though rare, could send sharp shards flying.

Stack boards neatly as they emerge from the outfeed side. Considerations like moisture content dictate how soon boards can be moved to storage.

With experience, you’ll develop a smooth cutting rhythm for efficient milling. But always prioritize safety by keeping hands clear of the blade path.

With practice following these steps, you’ll produce beautiful boards from even the gnarliest of culls! Correct technique leads to straighter cuts and less wasted wood.

Mastering Bandsaw Milling Techniques For Superior Lumber

Once you’ve gained experience with the basic milling process, it’s time to explore different sawing techniques that produce high quality lumber. Proper technique selection maximizes yield and exposes the most eye-catching grain patterns.

Plain Sawing cuts boards that are perpendicular to the growth rings. It yields the greatest footage but often includes unsightly defects across the grain. Good for dimensional lumber.

Quarter Sawing cuts parallel to the rays between the growth rings. More time consuming but accentuates beautiful linear grain. Ideal for furniture, flooring and veneer. Minimizes grain distortion.

Rift Sawing cuts at an angle between plain and quarter, following the rays at an oblique angle. Produces striking flecks and chatoyancy with less waste than quarter sawing.

Live Sawing involves leaving a portion of the bark and outer sapwood attached, known as a live edge. Creates an organic rustic appearance prized by live-edge furniture makers.

When possible, start plain sawing higher grade logs then transition to more intricate patterns lower. Mark grain direction clearly beforehand and allow for blade drift on tight quartered cuts.

With logs cut across their pith, consider breaking down the center section using plain cuts with bookmatched quartersawn slabs on either side.

Pay close attention to grain as you mill. Adapt techniques in real-time for optimal yield based on how the wood is recovering. Mastering techniques unlocks your mill’s full potential for superior results.

Essential Tips for Safe, Productive Milling

Now that you understand how to set up and mill lumber using different techniques, some final tips will ensure your experience is as safe and efficient as possible.

For safety, always wear appropriate protective gear – sturdy boots, gloves, ear and eye protection are minimum requirements. Long hair and loose clothing should be contained for their own safety near moving machinery.

Take time to tune up your mill before heavy use. Inspect all components for wear and make adjustments as needed. Ensure blade tracking is aligned to reduce vibrations.

Proper log preparation also boosts safety and yield. Remove limbs, trim ends square and flatten occasionally rounded bottoms to lay flat and stable on the deck.

Log feeding techniques should leverage the mill’s design – roll, push or let feeder rolls/ hydraulics slowly advance logs onto spinning blades. Never force wood into a spinning saw.

Adjust blade speed based on tooth configuration, wood species and desired cut surface. Slower speeds produce smoother finishes at the cost of slower cutting.

Maximize yield by flipping and turning logs partially cut to access all sides. With experience comes the ability to read grain flows and target figured sections.

With portables, make progressive milling a convenience by moving units alongside your work – cut logs on-site where they fall.

When milling is complete, clean and store your unit properly to minimize rust and maximize its resale value once upgraded. Regular maintenance extends equipment life.

Always put safety first, and your milling operation will become a profitable, low-waste wood processing system delivering beautiful lumber for years to come. Enjoy the process!

Troubleshooting for a Smooth Milling Experience

Even with care and experience, problems can arise during milling that require troubleshooting. Here are some common issues and their solutions:

Dull Blades: Dull or damaged blades cause burning, sniping, and wasted wood. Sharpen or replace blades promptly at the first signs of trouble.

Blade Alignment: Misaligned or poorly tracked blades can lead to uneven cuts or blade breakage. Check tensioning idlers regularly and adjust as needed.

Vibration: Vibration causes inaccurate cuts and operator fatigue. Check for worn bearings, tighten all fasteners, ensure smooth log movement.

Jammed Logs: Sometimes dense heartwood or slope of grain jams logs on blades. Avoid forcing, try alternate angles or hand-finishing with a saw.

Snipe: Wood chipping out past the end of boards. Adjust downfeed speed, rollout rollers, use backend snipeblocks, increase blade tension.

Chatter: Blade fluttering during cuts, causing roughness. Slow feed speed, increase blade/tip tension, resharpen blade.

Defects: Pin knots, internal cracks etc. identified after cutting. Learn to read grain lines better before milling.

With patience and an understanding of your specific mill’s quirks, most problems have fixes. Don’t hesitate to service components or consult dealer support documents. An efficiently running mill means straighter, more profitable lumber.

Bringing It All Together for Successful Lumber Milling

By following the steps outlined in this guide, you now have the fundamental knowledge necessary to confidently start sawing lumber with your bandsaw mill.

With some hands-on experience, your skills will continue growing to maximize efficiency and yield.

To review, we discussed how to choose the right mill for your budget and needs, ensure safe and proper setup, understand basic and advanced sawing techniques, operate efficiently, and troubleshoot common issues.

Mastering these aspects will allow you to take full advantage of the milling process.

Whether your goal is producing lumber for personal woodworking projects, supplemental income or large scale commercial endeavors, a bandsaw mill is a versatile tool when used correctly.

You’ll develop an appreciation for the variability in wood grain and properties between species.

As with any machinery, ongoing self-education is key. Continue honing blade maintenance and machine adjustments.

Learn from the experience of others in milling communities online. Read manuals cover to cover and heed all safety warnings. With time invested in training, your mill will reward through increased productivity.

Whether milling the occasional small tree or processing truckloads of logs, the satisfaction of turning raw material into finished wood products is immensely rewarding.

We hope this guide has provided a foundation for you to step confidently into the world of bandsaw lumber milling.

Taking Your Milling Skills to the Next Level

By now you have a solid understanding of how to safely and efficiently mill lumber using a bandsaw mill. But the learning doesn’t stop here.

As with any new skill, continuous practice and advancement will help you maximize your mill’s capabilities.

Consider taking a sawmill operation or maintenance course offered by equipment manufacturers like Wood-Mizer.

Hands-on training from industry experts can help troubleshoot complex issues and perfect your technique. Many also offer portable sawmill operator certifications.

Joining a local lumber milling group connects you with an experienced community. Attend meetings to observe advanced mill setups, receive milling assignments, and exchange knowledge with other operators facing similar conditions. Many groups even host milling bees and lumber swaps.

Advancing your skills into specialty or commercial uses generates additional income potential. You can start milling timber salvaged from construction sites or selective logging operations.

Custom milling for builders yields architectural grade lumber. Supplement your operation by offering portable milling services on location.

Invest in optional mill upgrades like additional blade speeds, hydraulic log handling systems, optimized sawhead carrier designs as your experience and throughput increase. Larger capacity mills allow processing more volume per day.

Always seek to improve safety procedures with your increased responsibilities. Consider LIABILITY INSURANCE in case of unforeseen accidents on-site. Maintain all equipment rigorously according to manufacturer guidelines.

With ongoing dedication to honing your craft, backyard or small-scale milling can grow into a serious small business. But always prioritize safe practices as your skills and abilities expand over the years of milling ahead.